Showroom

We are known as a reliable company of Footwear Machinery which is high in quality. It is trusted for its incomparable performance as well as long service life. Customers are more than satisfied by the prices of our product which are very affordable.

We are known as a specialist of Vertical Injection Moulding in which we are very much experienced. Customers are highly pleased by our reasonable prices which do not let them think twice before contacting our company which is their first choice.

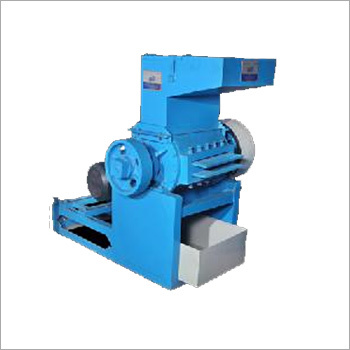

Granules Mixing Machine uses a common process phase in the creation of items for industries such as healthcare, milk, insecticides, cosmetics, cleaning products, pesticides, and plastics.To make a uniform, stable combination, a double-cone blender is utilized. This machine is checked under various parameters to ensure its high durability.

Send Inquiry

Send Inquiry Send SMS

Send SMS